MOTOR REDUCER INTEGRATED MACHINE

Adopt German Lenze brand motor and reducer all-in-one machine suitable for HVLS industry;

1. Adopting low backlash assembly process and gear grinding process, the noise is lower.

2. Strengthen the bearing frame structure, trapezoidal shaft structure, increase the oil seal, strengthen the fuselage structure, and have a higher safety factor.

3. IE2 high-effiffifficiency motor is used, which can save energy by 5-10% compared with IE1.

4. Passed CCC, CE, UL certifification.

CONTROL SYSTEM

Integrated controller and ABC VFD controller optional, imported brand Schneider electric control system, built-in safety protection module, automatically cut offff the power supply in case of accidents.

FAN BLADE CHASSIS

American Airlines AA7075 superhard aluminum alloy, made by Japan Co., Ltd., which has been focusing on aluminum alloy production for 60 years, is made by high-pressure precision forging (ob reaches 600Mpa), and the dynamic balance test is checked after CNC precision machining; ten times the force design, 40 years reliability life.

PLUG-IN

The plug-in plug-in structure is adopted, which is in contact with the inner cross-section of the fan blade, and the wear caused by the plug-in to the fan blade is relatively low. American Airlines AA7075 superhard aluminum alloy is made by Japan Co., Ltd., which has been focusing on aluminum alloy production for 60 years. High-pressure precision Forging molding, the density is as high as 2.8g/cm3, the cross-sectional area of the insert is increased by 30%, and the length of the connection with the fan blade is increased from the original 10cm to 19cm, which increases the stress performance and safety performance of the receiving area several times.

FAN BLADE

Six-blade propeller shape, the thickness of the blade reaches 2mm, double ribs, to ensure that the blade droop does not exceed 6cm, American Airlines imported high-performance aluminum alloy material: AA6063T6511; the surface is sprayed to facilitate cleaning the dust on the blades and grease.

MAIN FRAME

The steel structure is laser cut, and the support frame is strengthened. All joints are fully welded, which is solid and fifirm: the surface is electro-galvanized and will never rust: the industry's unique airflflow heat dissipation design prevents the motor from overheating and causing failure.

HARDWARE FASTENERS

Imported brand bolts, the highest strength 12.9 standard; DIN125A anti-loosening self-locking nuts; suspension fasteners use slotted positioning pin anti-loosening nuts; the driving device uses Loctite "Loctite" thread locking agent for permanent locking

CLIP FIXATION

The anti-slip groove design and cotter pin locknut completely prevent the steel beam clamping device from slipping and falling offff accidentally, without drilling and welding.

OTHER PRODUCT ACCESSORIES

Motor protection 304 stainless steel, molded steel bushing, LOGO components, aerodynamic tail, electrical installation group.

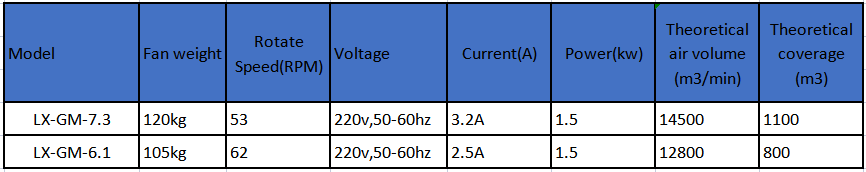

Technical Parameter:

Contact: Jane Tang

Phone: +8618051291581

Tel: +8618051291581

Email: janetang@liangxintech.com

Add: No. 62, Qilu Road, Yuanhe street, Xiangcheng District, Suzhou City, Jiangsu Province, China

We chat